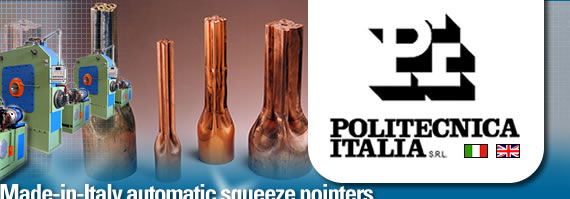

The line of hydraulic squeeze

pointers of the Afonat series represents the state-of-the-art

and most complete technological solution for making the tong-holds

of drawn pipes. The main feature of our machines is sturdiness

which, together with the use of very high quality component

parts (motors and Siemens operator panels, Bosch-Rexroth

hydraulic components, Moog pumps) ensures absolute reliability

over the years.

Another feature of our machines is the "follow-on" jaw

closing system, which mechanically ensures all 4 jaws move

at the same time and permits achieving any square end size

with just one type of jaw.

Force for cylinder 150 t

Maximum tube point length 280 mm

Maximum jaws opening 140 mm

Maximum jaws closure 10 mm

Hydraulic power unit

- Oil tank 950 lt

- n° 4 motors Siemens

- n° 4 pumps Moog

- Hydraulic components Bosch-Rexroth

- Distribution block steel

- Heat exchanger Air/oil or Water/oil

The Afonat series, starting with the 404 up to the 1004 consists

of two separate blocks: the main structure and the hydraulic

unit. These machines require the building of an appropriate

foundation.

Operator panel Siemens OP 170B

Lubrication system automatic (managed from OP170B)

From the Siemens OP170B operator panel, all the machine

functions can be controlled, from jaw opening/closing to

automatic greasing adjustment and the cleaning blower. The

type of cycle to be used - Automatic, Semi-automatic or Manual

- can also be selected from the panel.

See lay-out

2D->

Only for registered users

|